If an mbed prototype needs a custom enclosure, there are some low-cost web-based enclosure fabrication services that allow users to custom design a case and front panel using a free CAD tool. The CAD tool has cutouts for many of the standard computer connectors and allows the user to add custom labeling on the front panels. After an order is placed on the web, a computer numerical control (CNC) machine automatically cuts out the panels and mails them out in a couple days. One such web-based fabrication service is available at www.frontpanelexpress.com. Here is an image of a custom case some students made in a couple hours at frontpanelexpress.com for a recent project for under US $100. There is a small off-the-shelf microcontroller board hidden inside along with a battery pack and some ugly wires. In Europe, the frontpanelexpress service is also available at http://www.schaeffer-ag.de/.

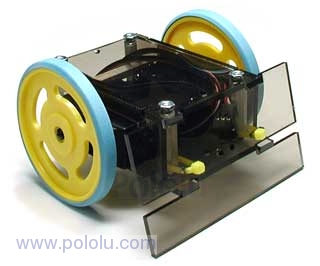

Many schools with a machine shop have CNC laser cutting and engraving machines that can also be used to cut plastic sheets for use in electronic prototypes and there are web-based laser cutting services such as the ones at Pololu and Ponoko . The sumobot plastic parts below cost $25 for two sets. Thicker or larger plastic sheets take more laser cutting time and cost more. Many of the commercial robot kits actually use laser cut parts.

To make rapid prototypes of 3D parts, one of the widely used 3D CAD drawing tools such as SolidWorks is used to generate a 3D model of the part. Then over the web you can upload your 3D CAD model of the part, get a quote online, order, and get the part back in the mail in a couple days. There are a number of web-based 3D printing services such as www.buildparts.com and www.quickparts.com and even low cost kits to build your own 3D printer such as those from www.makerbot.com seen below.

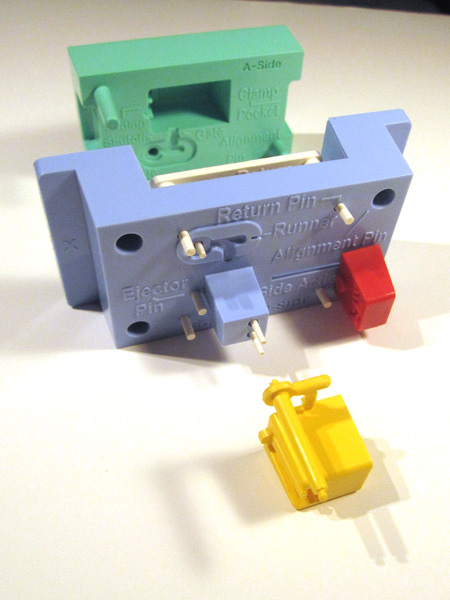

These are handy for quick mock-ups. 3D parts made using multiple axis CNC machines can use more durable plastics and even aluminum. One such 3D CNC web-based service is www.firstcut.com and another is www.QuickCutCNC.com . The minimum setup charge is around $100. Once a prototype has been evaluated and approved, if more than a dozen or so parts are needed it might make sense to switch to plastic injection molding using another web-based service such as www.protomold.com . The minimum setup charge to generate the mold for injection molding runs around $1,500, but it has a much lower unit production cost than CNC. A fast turnaround of a couple days is also possible with injection molding. Firstcut and Protomold are both divisions of www.protolabs.com and they have production facilities in the US, UK, and Japan. The low-cost molds will typically wear out after several thousand parts. If several thousand parts are needed later in mass production, a more traditional process for molding is typically used with an even higher mold setup fee but with a lower per unit cost. A sample of an injection molded plastic demo part from Protomold is seen below.

If an mbed prototype needs a custom enclosure, there are some low-cost web-based enclosure fabrication services that allow users to custom design a case and front panel using a free CAD tool. The CAD tool has cutouts for many of the standard computer connectors and allows the user to add custom labeling on the front panels. After an order is placed on the web, a computer numerical control (CNC) machine automatically cuts out the panels and mails them out in a couple days. One such web-based fabrication service is available at www.frontpanelexpress.com. Here is an image of a custom case some students made in a couple hours at frontpanelexpress.com for a recent project for under US $100. There is a small off-the-shelf microcontroller board hidden inside along with a battery pack and some ugly wires. In Europe, the frontpanelexpress service is also available at http://www.schaeffer-ag.de/.

Many schools with a machine shop have CNC laser cutting and engraving machines that can also be used to cut plastic sheets for use in electronic prototypes and there are web-based laser cutting services such as the ones at Pololu and Ponoko . The sumobot plastic parts below cost $25 for two sets. Thicker or larger plastic sheets take more laser cutting time and cost more. Many of the commercial robot kits actually use laser cut parts.

To make rapid prototypes of 3D parts, one of the widely used 3D CAD drawing tools such as SolidWorks is used to generate a 3D model of the part. Then over the web you can upload your 3D CAD model of the part, get a quote online, order, and get the part back in the mail in a couple days. There are a number of web-based 3D printing services such as www.buildparts.com and www.quickparts.com and even low cost kits to build your own 3D printer such as those from www.makerbot.com seen below.

These are handy for quick mock-ups. 3D parts made using multiple axis CNC machines can use more durable plastics and even aluminum. One such 3D CNC web-based service is www.firstcut.com and another is www.QuickCutCNC.com . The minimum setup charge is around $100. Once a prototype has been evaluated and approved, if more than a dozen or so parts are needed it might make sense to switch to plastic injection molding using another web-based service such as www.protomold.com . The minimum setup charge to generate the mold for injection molding runs around $1,500, but it has a much lower unit production cost than CNC. A fast turnaround of a couple days is also possible with injection molding. Firstcut and Protomold are both divisions of www.protolabs.com and they have production facilities in the US, UK, and Japan. The low-cost molds will typically wear out after several thousand parts. If several thousand parts are needed later in mass production, a more traditional process for molding is typically used with an even higher mold setup fee but with a lower per unit cost. A sample of an injection molded plastic demo part from Protomold is seen below.